- Startseite

- >>

- Nachrichten

- >>

- Seite 9

Nachrichten Liste

Wir freuen uns, Ihnen die Ergebnisse unserer Arbeit und die Neuigkeiten unseres Unternehmens mitzuteilen und Sie rechtzeitig über die Entwicklungs- und Personaleinstellungs- und Umzugsbedingungen zu informieren.

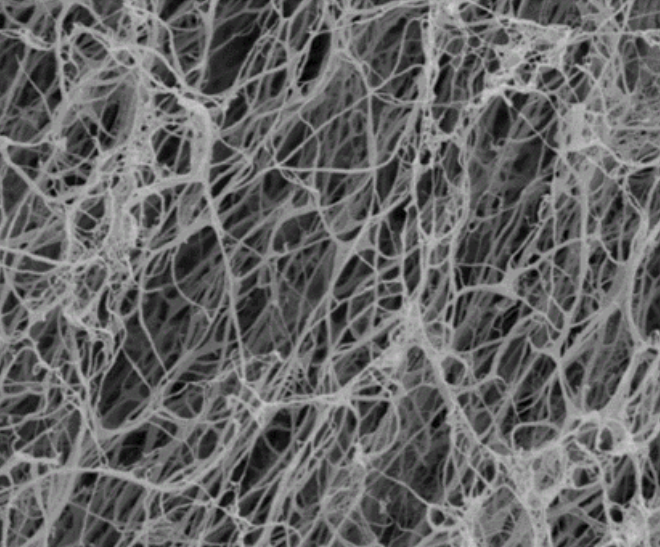

PVA fiber for concrete (or mortar) is an ideal environment-friendly cement reinforcement material, because of its unique molecular structure, it has good affinity with cement, and has good alkali resistance and weather resistance. Adding PVA fibers to cement concrete (or

The main disadvantage of polyvinyl alcohol fiber is poor dyeability, low dyeing amount, and not bright color. This is because the fiber has a skin-core structure and some hydroxyl groups are blocked by acetalization. In addition, the hot water resistance

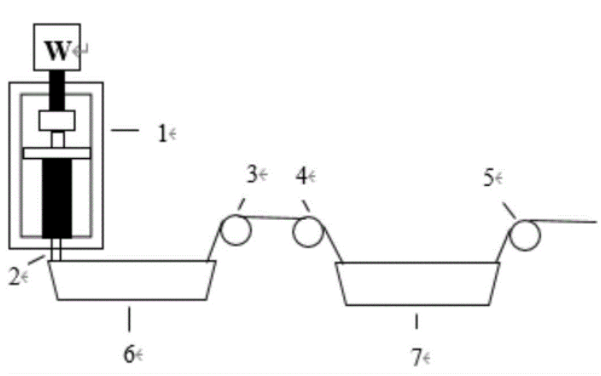

High-strength polyvinylalcohol fiber is a fiber obtained by jelly spinning or wet spinning and high-stretching of polyvinylalcohol with a high degree of polymerization. For example: after the jelly yarn spun with dimethyl sulfoxide/water (8/2) mixed solvent is stretched by 48

Polyvinyl alcohol fiber can be blended with other fibers, and then dissolved after textile processing to obtain high-grade spun yarn textiles, and can also be made into non-twisted yarn or non-weft blanket. It can also be used in papermaking as

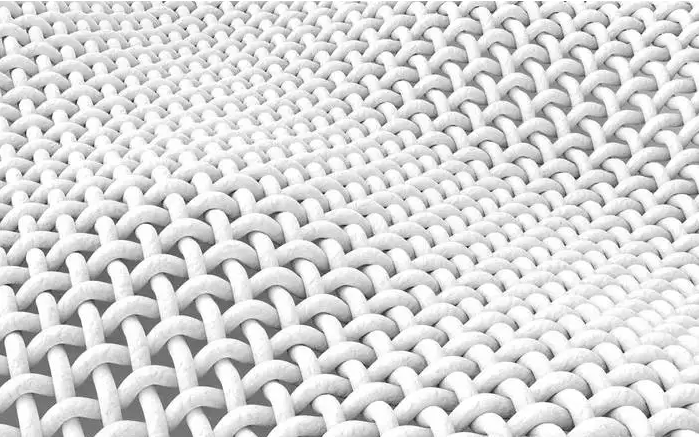

Polyvinyl formal fibers are used in the industrial field to make canvas, tarpaulins, filter cloths, conveyor belts, packaging materials, work clothes, fishing nets and cables for offshore operations. High-strength, high-modulus filaments can be used as skeleton materials for conveyor belts,

It has good mechanical properties, high strength, high modulus and low elongation. Strong acid and alkali resistance and chemical resistance. Light resistance: under long-term sunlight, the fiber strength loss rate is low. Corrosion resistance: Fiber buried underground for a long

The average molecular weight of the raw material polyvinyl alcohol used for the polyvinyl alcohol fiber is 60,000-150,000, the thermal decomposition temperature is 200-220°C, and the melting point is 225-230°C. Polyvinyl alcohol fibers can be obtained by wet spinning and

In the early 1930s, the German Wacker Chemical Company first produced polyvinyl alcohol fibers. In 1939, Japan’s Sakurada Ichiro, Yazawa Jiangying, and North Korea’s Li Shengji treated this fiber with formaldehyde to obtain heat-resistant polyvinyl formal fiber. ) to build

Synthetic fiber made by spinning polyvinyl alcohol as raw material. The polyvinyl formal fiber obtained by treating this fiber with formaldehyde is called vinylon in China and vinylon in the world. The fibers obtained by spinning relatively low molecular weight

The main features of polyvinyl alcohol fiber are high strength, high modulus, low elongation, wear resistance, acid and alkali resistance, good weather resistance, good affinity and bonding with cement, gypsum and other substrates, and are non-toxic and non-polluting , does